The REAL Job of a Millwright

When your industrial equipment breaks down and everything’s on the line — who do you call?

You’re in the shop. The line’s loud. A motor’s overheating. A belt’s slipping. The crew’s watching. Orders are backing up. And now the mixer’s down.

If you manage a plant, factory, or ag operation, you’ve likely been here before. You know how fast a millwright can help you recover — and how much downtime really costs.

A good millwright delivers proactive maintenance, precision repairs, and the skill to keep your line moving — safely, efficiently, and without guesswork.

They should be your first call. And on speed dial.

What Does a Millwright Actually Do?

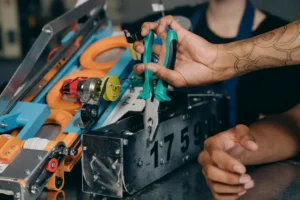

Millwrights install, repair, and maintain industrial equipment — the heavy machines that keep your plant, shop, or operation running. They’re who you call when things go wrong — or better yet, before they do. If you’ve ever searched:- “Machine down, who to call?”

- “Industrial equipment repair near me”

- “Emergency plant repair services”

- Machine installation Setting up new lines, conveyors, or machinery. Reading blueprints. Hooking into industrial electric and controls. Aligning shafts. Doing it right the first time.

- Preventative maintenance Catching wear early, replacing tired parts, keeping things moving without needing emergency repairs.

- Repairs & troubleshooting

- Factory equipment troubleshooting support is in their DNA. They don’t just patch problems — they find the root cause and fix it for good.

- Breakdown repair When you’re losing hours and money, a good millwright brings the right tools, skills, and urgency.

- Rigging and moving Millwrights handle tight moves and heavy lifts safely and cleanly — without tearing up your shop floor.

- Metal fab & welding Can’t find the part? They’ll design, metal fabricate, and weld one from sheet metal or plate. Guards, brackets, fittings — whatever you need.

- Machining In-shop or onsite, they can mill, drill, or lathe parts to exact specs — so you’re not waiting days for shipping.

- Hydraulic & pneumatic systems Pumps, cylinders, valves, hoses — they know how to fix pressure problems fast.

- Balance & alignment Misalignment causes wear, noise, and heat. Millwrights use precision tools to keep your machines running smooth and quiet.

Millwright vs Mechanic: What’s the Difference?

It’s a fair question. A mechanic fixes cars, trucks, or small engines. A millwright works with big, industrial machines — setting them up, tearing them down, and keeping them running day in and day out. They’re trained across electrical, hydraulic, welding, metal fab, and machining work. When you search “Who fixes industrial machines?” — you’re looking for a millwright.What to Look For in a Good Millwright

If you’re hiring, subcontracting, or just looking for backup, here’s what matters:-

- ✅ Real-world experience — not just book knowledge

- ✅ Precision — someone who checks alignment down to the decimal

- ✅ Safety-first mindset

- ✅ Skill in welding, machining, metal fabrication, and troubleshooting

- ✅ Knows how to work under pressure

- ✅ Doesn’t guess. Asks the right questions. Fixes it right the first time.

Why It Matters to You

Every plant has “That Day”. The one where something breaks, the whole crew stops, and no one knows what to do. A good millwright can be the difference between 8 hours lost and 8 minutes. They:-

-

- Prevent breakdowns

- Help avoid expensive emergency calls

- Keep your people safe

- Get you back online faster

-

They don’t just show up with a toolbox. They show up with answers too.

Is Being a Millwright a Good Job?

Yes — and if you’re thinking about hiring one, it helps to understand why. It’s hands-on, steady work with strong demand across the manufacturing industry. Millwrights learn welding, machining, metal fabrication, and how to handle industrial machines under pressure. For business owners and plant leads, bringing in a millwright is like bringing in your own industrial insurance plan.Where Millwrights Work

You’ll find them wherever machines need to run right:-

-

- Factories and food plants

- Agriculture and grain handling

- Machine shops

- Mills and foundries

- Power plants and mining operations

- Construction and industrial facilities

-

Bottom Line

A millwright doesn’t just fix broken equipment. They stop problems before they start. So next time something’s off — something rattles, squeals, or shuts down — skip the guesswork.Problem Solved.

Equipment Repairs, Maintenance, and Custom Fabrication—All in One Place. Whether you’re facing a breakdown or planning ahead, we’ve got the crew, the tools, and the experience to keep your plant running.-

-

- 📞 Call us today to get a millwright on site — fast.

- 📧 Have a question? Reach out anytime.

- 🛠️ Need a quote? Click here to request one now.

-