Metal Cutting & Design Precision services are essential in metal cutting: from Alberta's oil fields to the plains of Saskatchewan & Manitoba

Precision in Western Canada

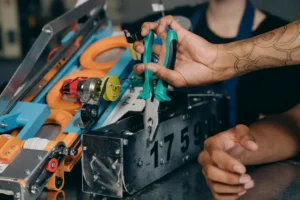

Metal cutting is a meticulous process where unwanted material is removed from a metal block, often using sophisticated tools to achieve the desired shape and size. This practice, pivotal in metal fabrication, is essential for the agricultural and industrial realms of Western Canada.

Precision services are essential in metal cutting in Alberta’s oil fields and the plains of Saskatchewan and Manitoba.

The Essence of Metal Cutting

CNC Laser Cutting and Waterjet Cutting

CNC laser cutting is very precise and efficient, cutting materials of different thicknesses with minimal waste and high accuracy. It’s a process that keeps the metal strong and makes parts with smooth edges, ready to use right away. This method is essential for industries requiring intricate metal designs and tight tolerances.

Waterjet cutting offers a complementary approach, distinguished by its ability to cut without introducing heat. This characteristic is crucial for materials sensitive to thermal distortion, preserving the metal’s inherent properties. With its capacity to cut a diverse range of materials, waterjet cutting is a versatile tool in the metal fabrication toolkit, catering to a broad spectrum of industrial applications.

Design and Customization in Metal Work

Transitioning from cutting processes to design, metal work embodies a seamless blend of functionality and aesthetics. Custom projects serve as a canvas where ideas are transformed into tangible products, harmonizing design with utility. This stage is pivotal, especially in environments demanding robustness, like agricultural machinery, or precision, such as in architectural projects. It’s where metal assumes its final form, ready to withstand the rigors of its application while enhancing its surroundings.

Maintenance & Repair: The Unsung Heroes

Custom Millwright Services: Your Strategic Partner

Our role transcends that of a mere service provider; we engage as a dedicated partner committed to propelling your projects towards operational excellence and success. This partnership approach ensures that we not only understand the intricacies of your project requirements but also align our services to bring your vision to fruition with precision and efficiency.

Selecting Custom Millwright Services means opting for a partner who understands the nuances of metal machining and the importance of precision in every cut and design. Our unique approach combines metal fabrication expertise with industrial repair capabilities, ensuring that your projects are not only well-designed but also supported by robust maintenance services.Crafting the Future with Precision

In Western Canada’s dynamic industrial landscape, the demand for precise and reliable metal cutting and design services is ever-present. Custom Millwright Services is poised to meet this demand, bringing a blend of expertise, precision, and innovation to the table.

Our commitment to quality and our comprehensive service range make us the go-to choice for industries looking to not just meet but exceed their metal work requirements.