Six practical steps top operators use to plan, prep, and execute a successful shutdown — and get back up faster.

- Catch equipment issues early, before they break down in the middle of a busy season

- Improve safety and compliance with inspections and repairs that actually get done

- Increase efficiency by cleaning, aligning, and upgrading equipment

- Avoid emergency breakdowns and the high price tag that comes with them

- Give your crew a well earned break, which pays off in morale and retention

- Get ahead of next season instead of constantly reacting to problems

Yes, downtime costs money. But unplanned downtime costs more, and it usually hits when you can least afford it. Let’s walk through the steps to plan a shutdown that works.

-

-

Build Your Shutdown Plan Early

- Track small repairs all year so nothing gets missed

- Prioritize based on MTBF (Mean Time Between Failure) and equipment condition

- Plan major upgrades and replacements at least 1–5 years out

- Task lists (including who’s doing what)

- Equipment parts + inventory review

- Rentals and tooling needs

- Safety protocols

- Security (cameras, locks, site access)

- Tech systems and software — is it time for training or upgrades?

- Scaling — if production grows next year, what bottlenecks can you fix now

Set Clear Roles and Timelines

Make a Communication Plan

- Who needs to know what — Maintenance leads, operators, vendors, security… not everyone needs every detail, but no one should be left guessing.

- When updates will happen — Daily check-ins, shift-change briefings, mid-shutdown reviews. Keep it predictable and consistent.

- How you’ll share info — Whether it’s whiteboards, radios, text threads, or a shared app, make sure everyone knows where to find updates.

- Who to contact when issues come up — Set a clear chain of contact for reporting delays, hazards, or equipment surprises.

Prep Before You Power Down

- Risk assessments and mitigation

- Equipment inspections ahead of shutdown

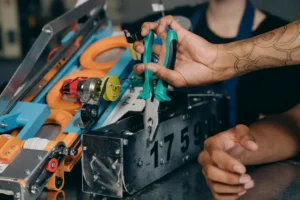

- Crew training for any new systems or tech

- Contingency plans — if something doesn’t go to plan, what’s Plan B?

Execute With Focus

- Track progress against your timeline

- Monitor quality of work as it happens

- Stick to safety protocols every step of the way

Pre-Schedule Your Shutdown Review

- Did everything get done on time and to standard?

- What went smoothly — and why?

- What caused delays or confusion?

- What needs to be done differently next year?

Start by creating a shutdown checklist. Not just the obvious wear items — think long-term.

Assign work based on each tech’s strengths. Not every mechanic is suited to every task — line that up early. Then build a realistic timeline with milestones. Pad it a little. Rushing maintenance leads to mistakes — and do-overs cost more than doing it right the first time.

Don’t assume people will “just know” what’s happening. When communication breaks down, tasks, safety checks, and timelines can get missed.

Your crew is closest to the work and often the first to spot problems. Make it easy for them to speak up, stay informed, and know exactly who to go to when something needs attention.

Build a simple, clear communication plan that covers:

Follow through, and you’ll keep your crew informed, your shutdown on track, and your operation running safer and smoother.

You don’t want to be halfway into a shutdown and realize you’re missing parts, tools, or training. Pre-shutdown prep should include:

Once things are shut down — stick to the plan but stay flexible enough to adapt.

If you don’t book it, it won’t happen. And it needs to.

Before the shutdown even starts, set a date for the review. Once production ramps back up, things get busy — and it’s easy to skip the debrief. But this step is what turns a good shutdown into a better one next time.

Here’s what to cover in your review:

Capture it while it’s still fresh. Bring in the crew, jot it down, and file it somewhere you’ll actually find it. Next year’s shutdown will be better for it.

-

BONUS: Best Practices from Top Operators

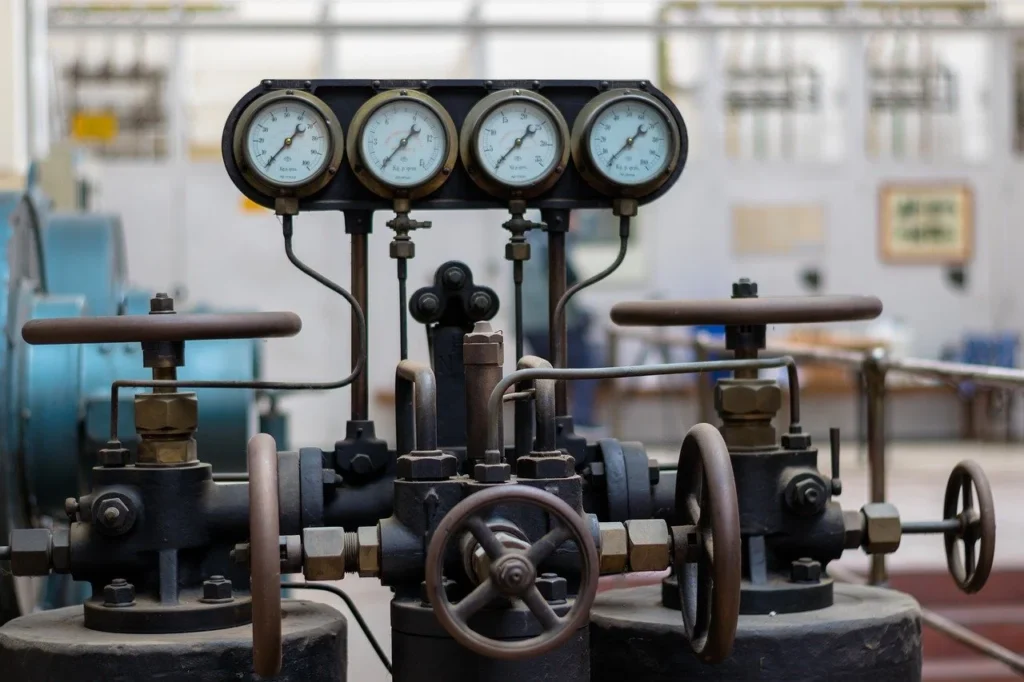

Prioritize Preventative Maintenance

Don’t wait until something breaks. Fix it before it costs you.Use Technology

Track your shutdown tasks, timelines, and issues with digital tools. Real-time updates beat guesswork.Train Your Crew

Ongoing training builds confidence and cuts errors. Skilled techs work faster and safer.Listen to the People on the Floor

No one knows the equipment better than the folks running it. Give them a voice — and use it.Bring in the Right Help

Complex repairs or upgrades? Call in pros who’ve done it before. Welding, fabrication, conveyors, automation — don’t DIY something critical just to save a buck.

Where Custom Millwright Services Fits In

We know the drill. Every operation is different — but the goal is the same: keep things running safely and efficiently.

A planned shutdown isn’t wasted time. It’s your chance to reset, refocus, and get back to production with fewer surprises and a lot more confidence.

Take care of your equipment. Take care of your people.

- A scheduled shutdown maintenance plan

- Emergency industrial repairs

- Welding, steel fabrication, or conveyor systems

- Installing new equipment or automation systems