In any industrial setting, mechanical machinery is the backbone of production. Whether it’s motors, pumps, conveyors, or presses, keeping this equipment in top working condition is crucial. Breakdowns can cost thousands of dollars in downtime, repairs, and lost productivity. Every plant manager should have a strong preventative maintenance (PM) program. This should start with one important tool: the industrial maintenance log.

Industrial maintenance logging is more than just a checklist. It’s a living document -a digital record that tracks the health, service history, and planned care of every piece of equipment. It serves as the foundation for data-driven decisions, safer operations, and long-term cost savings.

Log data is essentially useless if it is:

- too vague to be useful

- too detailed to keep up with

-

or totally ignored until something goes wrong

This article explains the essential items every industrial maintenance log SHOULD include and how to incorporate digital tools to make the process efficient, accurate, and actionable.

1. Equipment Identification

Every maintenance log must begin with clear identification of each machine. This section should include:

- Equipment name or type

- Manufacturer

- Model and serial number

- Internal asset ID (if used)

- Location in the facility

- Installation date

Why it matters: Proper ID ensures maintenance tasks are performed on the correct asset. It also helps technicians quickly locate machines, reference manuals, and order the right replacement parts.

2. Planned Maintenance Schedule

The heart of preventative maintenance is timing. Your log should outline:

- Routine inspection intervals (daily, weekly, monthly, quarterly, yearly)

- Service intervals (based on hours of operation or calendar dates)

- Manufacturer-recommended scheduled maintenance guidelines

Why it matters: A well-planned schedule prevents breakdowns by catching wear and tear before it causes failure.

Pro Tip: Don’t just close the loop. Set up the next one. Every log entry should end with:

- “Next check: ____”

- Or “Monitor again in 7 days”

- Or “Add to shutdown checklist”

3. Task Descriptions

For every scheduled service, provide a clear and specific task list, such as:

- Lubricate bearings

- Replace filters

- Check and tighten belts

- Inspect electrical connections

- Clean cooling fins

Why it matters: Detailed task descriptions reduce the chance of skipped or incorrectly performed maintenance. They also help new technicians follow standard procedures.

Pro Tip: Sounds basic, but most logs stop at “lubricated.” What kind of grease? How much? Any notes on contamination, colour, or residue?

Better logs include:

- Type of grease/oil used

- Quantity

- Location (esp. if multiple zerks or lube points)

- Date & initials

Pro Tip: Note any parts replaced — even if it’s “minor.” One bolt change might not matter today, but in a breakdown review, it might tell you everything.

4. Assigned Personnel

Record who is responsible for each maintenance task:

- Technician or maintenance team name (especially if using a commercial maintenance provider)

- Contact information

- Certification or qualification if required (e.g., licensed electrician)

Why it matters: Accountability ensures tasks get done on time and by qualified staff. It also aids follow-up if issues arise.

5. Work History and Notes

- Date and time of service

- Technician name

- Observations or issues noted

- Parts replaced or used

- Time spent on task

Why it matters: A detailed history allows trend analysis (e.g., recurring failures), warranty verification, and informed decision-making for repairs or replacements.

Pro Tip: The person who operates the equipment every day knows what it’s supposed to sound, smell, and feel like. So let them log it. Include a section for operator notes on every inspection:

- “Motor sounds rough on startup”

- “New vibration since Monday”

- “Temp’s been higher than normal but no alarms”

You’ll catch more issues early — and build trust with your team while you’re at it.

Pro Tip: Ticking a box that says “checked the belt” doesn’t tell you anything. What was the belt tension? Any visible cracking? Was it aligned properly? Use a simple rating scale (1–5) or quick comments like:

- Minor wear — recheck in 30 days

- Replace at next shutdown

- No issues — tension OK

6. Downtime and Failure Records

Track unplanned outages and failures:

- Date and duration of downtime

- Cause of failure

- Emergency actions taken

- Parts replaced

- “Root Cause” analysis notes

- Did the industrial repair require outside contractors? Who?

Why it matters: Knowing what went wrong helps prevent future incidents. Over time, this data supports strategic investments in upgrades or redesigns.

7. Parts and Inventory Information

List parts used during maintenance and what is in stock:

- Part name and number

- Quantity used and remaining

- Storage location

- Supplier and reorder information,

- Lead time for key parts

Why it matters: Keeping an eye on inventory helps avoid delays due to missing parts and allows bulk purchasing or vendor negotiations.

Pro Tip: Digital maintenance logs allow the storage of a LOT of information. Be creative in what information you store. Detail notes about specialty tools that may be required, location of service manuals, special techniques required to perform maintenance.

8. Safety Checks and Compliance Logs

Record inspections tied to safety and regulations:

- Guard and shield checks

- Lockout/tagout verification

- Emergency stop functionality

-

OSHA or industry-specific compliance records

Why it matters: Maintenance and safety go hand in hand. Recording these checks protects workers and supports audit readiness.

Pro tip: Safety logs are separate from maintenance logs in most operations — and that’s fine. But your maintenance log should still flag:

- Hot work done

- Confined space entry

- Any newly recognized safety hazards

- Anything requiring special PPE or lockout

It helps with review, training, and risk assessment. And when you’re trying to improve your safety procedures, it’s all relevant.

9. Digital Integration and Automation

While traditional paper logs can work, digital tools offer major advantages. Consider using Computerized Maintenance Management Systems (CMMS) or cloud-based platforms that offer:

- Automated reminders and schedules

- Centralized access via mobile or desktop

- Real-time data entry and dashboards

- Digital asset tagging (e.g., QR codes or RFID)

- Integration with inventory systems and purchase orders

Some of the best well known systems include Cryotos, Limble CMMS, Fiix CMMS, UpKeep, Accruent FAMIS 360, and MaintainX.

Why it matters: Digital systems reduce paperwork, prevent errors, and provide better visibility into operations. They make it easy to analyze trends, share reports, and adapt to production changes.

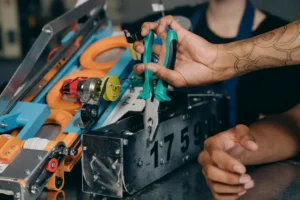

10. Visual and Condition Monitoring Data

Modern maintenance goes beyond wrench-turning. Add data from sensors and visual inspections, such as:

- Vibration analysis

- Thermal imaging

- Oil sampling results

- Visual wear photos and videos

Not everything is mechanical. Sometimes it’s 38°C in the shade, and your motors are cooking in a tin-roof bin.

Log:

- Ambient temps (if extreme)

- Dust conditions (was there cleaning nearby?)

- Moisture / condensation / leaks

Canadian summers and winters both bring challenges — and this context can explain a lot when reviewing failures.

Why it matters: Predictive maintenance tools let you catch problems before they cause downtime. Logging this data improves diagnosis and future forecasting.

Pro Tip: Encourage your workers to grab a quick picture or video when equipment misbehaves. Train them how to attach the media to a log. You might even consider an incentive program to encourage them to spot and report equipment problems before they get out of hand.

Getting Started: Practical Tips

- Start small: Pick one or two critical machines and build logs for them.

- Use templates: Many CMMS platforms provide customizable templates.

- Train your team: Make sure technicians understand how to log data and why it matters.

- Review regularly: Use maintenance logs in weekly or monthly meetings to guide decisions.

- Tie logs to KPIs: Metrics like Mean Time Between Failures (MTBF) and maintenance costs help track success.